Add to Cart

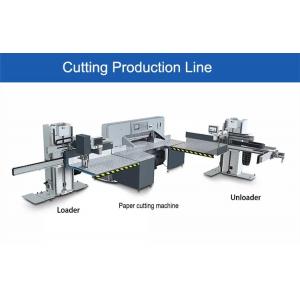

The paper cutter Guillotine is a traditional product, which is used to deal with the paper cutting requirements in the later stage of printing. From the mechanical paper cutter to the tape-controlled paper cutter, and to the cutting system of microcomputer program control, color display, full image operation guidance visual processing and computer-aided cutting external programming and editing production data, the production preparation time is reduced. Shorter, more precise cutting, less labor-intensive, and safer to operate.

1.Double Hydraulic Device: the hydraulic system adopts the Germany advanced technology. Equipped with combined hydraulic valve, double hydraulic controlling structure, it approves hydraulic device greatly. The hydraulic device pass CE certificate.

2.Double Guide Device: the paper pusher adopts double imported linear guide and roller ball screw., which can prolong the machine use life, and can bear the high speed paper delivering.

3. Photo cell: it is equipped with a photo cell safety protection device.

4.Over load protection device; convenient knife changing device.

5.Worktable chrome treatment: the worktable and side board surface are all adopted chrome treatment to improve the precision and quality of the machine.

6.Air ball: air balls are installed in the worktable. The paper sending work will be easy and accurate.

7.Cutting controller:both of the user's hands operate the machine. It can cut paper in one time.

8. Electronic knife lock:when the machine is malfunction, the electronic knife lock will lock the knife, and the machine will stop cutting to protect safety.

Main Technical Parameters

| Specification | Units | ECOO1150DH-10 | ||

| Max cutting width | cm/inch | 115/45.3 | ||

| Max cutting length | cm/inch | 116/45.7 | ||

| Max cutting height | cm/inch | 16.5/6.5 | ||

| Width of machine | With sidetable | cm | 267 | |

| Without sidetable | cm | 237 | ||

| Main motor | kw | 4 | ||

| Weight | kg | 3300 | ||

| Voltage | V | 365-395 | ||

| Cutting speed | Cycles/min | 45 | ||

| Packing size | L×W×H (cm) | 260×154×203 | ||

| Total width of machine | cm | 267 | ||

| Total length of machine | cm | 261 | ||

| Total height of machine | cm | 163 | ||

| The length of side table | cm | 70 | ||

| The width of groundsill of machine foot | cm | 60 | ||

| Clamp pressure | Min | N | 200 | |

| Max | N | 40000 | ||

| Knife thickness | cm | 139x16x1.37 | ||

| Grinding reserve | cm | 6 | ||

| Min cut | without false clamp | cm/inch | 3/1.2 | |

| with false clamp | cm/inch | 10/3.9 | ||

| Cutting speed | Cycles/min | 45 | ||

1 Touch screen input. 2 Automatic operation

11 Mandatory stop sending paper

12 .Mandatory stop cutting

Sheet-fed paper cutter is a kind of cutting machine, which is widely used and can be used for cutting paper, leather, plastic, cardboard and other materials. The paper cutter is mainly composed of a main engine (also known as a gantry), a worktable, a paper pushing mechanism, a paper pressing mechanism, and a cutting mechanism. T

The production of printing, packaging, bookbinding and other production from cutting to printing finished products and the cutting of raw books after binding all require paper cutters for cutting, so paper cutters are important equipment for post-press processing. Sheet-fed paper cutters are widely used in printing plants, bookbinding plants, packaging plants, paper products processing plants, etc.

Computer function:

1 Touch screen input.

2 Automatic operation

3 Semi-automatic operation

4 Manual operation

5 Demonstration

6 Automatic precise position

7 Manual position

8 Paper sender moves forwards and back wards.

9 Paper sender automatically accelerant or decelerate

10 Compulsory new direction

11 Mandatory stop sending paper

12 Mandatory stop cutting

13 Air pump works

14 Manual air blow control

15 Automatic seek origin

16 Automatically clear the origin error

17 Personalized programming mode

18 Division

19 Isometry

20 Insert cutting manual

21 Program browse

22 Chinese and English

23 Units change

24 Time

25 Skip cutting

26 Micro adjustment

27 Self-diagnose malfunction

28 Animate machine working process

29 Operator can set password for starting the machine

30 Count cutting datum

31 Amend paper shift

32 Sequence label

33 It can save 5000 program files

34 The storage time can reach 300,000 hours

35 Adjust the paper-sending speed

36 Safety warning

1. what about the payment term?

Normally, 30% deposit, 70% before shipping, or LC at sight.

2. What is the Lead Time ?

Usually 30-40 days, and we will try our best to meet your demands.

3. What about the Installation and After-sales technician support ?

Our engineers are all can go to help the installation and provide the necessary training. The buyer should take the round air tickets and service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours.

4.Do you have any other products?

We also offer other postpress machines for package and label printing companies, like UV coating machine, laminating machine, window patching machine, carton inkjet printing machine and digital label printing machine, thermal paper slitting machine.